Mills were an important part of life in the 18th century; in fact they were the first factories. Mills were an important part of the economy of the cities and towns that grew up around them. They provided lumber for shelter, iron for pots, pans and other implements and flour for bread. Mills produced manufactured goods for the overseas trade.

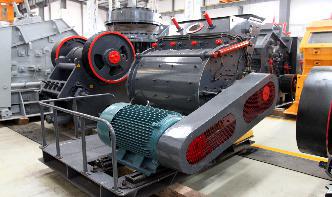

Construction Waste Recycling Crusher and Grinding Mill: In the field of construction waste recycling, construction waste processing equipment plant is professional crushing screening equipment for construction waste recycling. It integrates the vibrating screen, feeder, belt conveyor, primary, secondary and tertiary crusher and grinding machine.

Highpressure Suspension Mill >> EMail:joyal >> Http:// Features Compared with the common 5R4119 Raymond Mill under the same power conditions, the output of the machine is increased by 10%. Under the performance of highpressure springs, the rollers grinding pressure on raw

Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; Residence time of the material in the mill chamber. The size, density and number of the balls. The nature of the balls (hardness of the grinding material) Feed rate and feed level in .

Sep 09, 2018· Raymond mill is applicable to the grinding and processing of more than 280 kinds of nonflammable and nonexplosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as ba...

Apr 25, 2017· Gristmills. The most common use of water mills historically and in modern day developing countries is for grinding grains into flour. These are called gristmills, corn mills or flour mills. Early wheel design in ancient Greece and Rome employed horizontal paddles that were called Norse wheels.

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

Safe work practices Grinding machine Tool/Work rest • The work rest must be securely clamped and the gap between the tool rest and wheel must not be more than 3mm. • The work rest height must be on the horizontal center line of the machine spindle. • The rest must never be adjusted while the wheel is in motion as the work rest may slip and strike the wheel

Grinding Mills Construction And Working Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

The grinding of grain was the first incentive early man had to devise some sort of grinding apparatus powered other than by hand. The word "mill" is used in connection with a place or apparatus where grain was ground. The miller is who attended the mill and performed the duty of .

Raymond Mill Working Principle. The Raymond Mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts. Of them, the host is made up of a frame, an inlet volute, a shovel blade, grinding rollers, a grinding .

construction and working of electric iron – Grinding Mill ... construction and working of iron box– Rock Crusher Mill . construction and working of iron box is a leading global manufacturer of crushing and milling equipment (construction and working of iron box), also supply .

The material to be reduced determines the rotor construction of a Stedman Hammer Mill. The rotors used in the Type A hammer mills are adjustable to compensate for wear. Shattering by revolving hammers; Impaction against housing liners; Grinding on the adjustable grinding plate; Shearing by the grate bars or screen Type B "Down Running" Hammer Mill

For a mobile crusher, it is mainly including solid frame, impact crusher, feeder, vibrating screen, conveyor belts, motors and control boxes. The Mobile Crushing Station is widely used in mining, coal, refuse and recycling of construction waste, earthwork, urban infrastructure, roads or construction sites and other venues operations.

grinding equipment working principle and . working principle of GLASS GRINDING MACHINE in working principle of GLASS GRINDING MACHINE in Coimbatore, Construction ... Working Principle And Construction Of Flour Mill Motor

ensp·enspmill for grinding alfalfa hay Grinding Mill mill for grinding for the ground solid matter in this formula Grinding machines In md construction. Alfalfa Mills ThomasNet 201869ensp·enspThis industrial directory contains a broad range of Alfalfa Mills Custom manufacturer of mills for grinding alfalfa.

Unlike traditional mills, this unique type of mill mechanism allows you to trim the shaft to any length for ultimate customization. The truly innovative design of the CrushGrind® mechanism along with its advanced ceramic construction consistently provides smooth, reliable grinding to last a lifetime. Ideal for grinding pepper, salt, and dry spices

The Excavator Mill is an asphalt milling attachment for excavators. When connected to the backhoe remote hydraulic system, the Excavator Mill becomes a tool for asphalt repair, concrete cuts and grinding of shelf rock or outcroppings in construction work. The Depth Gauge allows the operator to preselect the cutting depth from flush to max.

Thanks to its robust design, the Disc Mill DM 200 can be used under rough conditions in laboratories and pilot plants, as well as online for the quality control of raw materials. The powerful DM 200 requires only a few minutes to achieve the desired grind size.. Application Examples. bauxit, cement clinker, chalk, chamotte, coal, coke, concrete, construction waste, dental ceramics, dried soil ...